How the Port is using renewable diesel to make a cleaner community

Imagine a fuel that could be made from just about any biological material: cooking oil, animal fats, even invasive weeds. A fuel that would drastically cut harmful pollution. A fuel that’s just as efficient as petroleum-based fuels.

It exists: It’s called renewable diesel, or RD. And the Port of Portland is using it to fuel many of its operations at the Port and PDX — benefitting climate, air quality and the health of employees and surrounding communities along the way.

Supporting environmental justice and community

Diesel particulate matter is one of the most harmful air pollutants. Due to their proximity to construction sites, industrial facilities, rail lines, transportation and freight hubs and corridors, marginalized neighborhoods in North Portland are disproportionately exposed to diesel pollution.

The Port of Portland has long-established emissions reductions goals and projects to minimize the impact on the people who work at, travel through and live near Port facilities. Applying an equity lens to the Port’s work increased the urgency to find comprehensive solutions to tackle the problem, and further solidified the Port’s priorities around environmental justice and air quality.

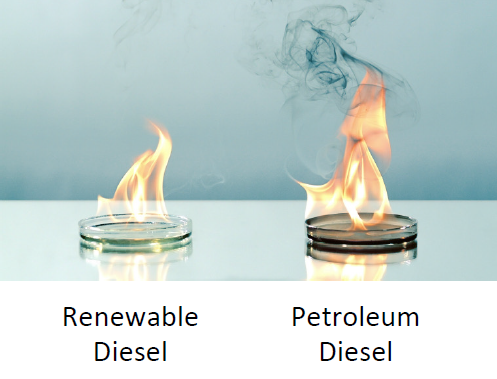

Renewable diesel is a near-term, high impact strategy that reduces diesel particulate matter by up to 30 percent and lifecycle greenhouse gas emissions by up to 80 percent.

“Our health is obviously impacted by air quality,” said Andrea Caudill, Senior Air Quality and Energy Specialist at the Port. “The air toxins in our region affect workers at PDX, marine and the surrounding communities who are often marginalized. By implementing a non-petroleum-based fuel, we are no longer introducing new fossil fuels into our atmosphere through extraction, refining, and emissions.”

What is renewable diesel, anyway?

Although RD is sometimes confused with biodiesel, the two fuels are not the same. They’re both produced from agricultural waste products, like used cooking oil and grease. But RD and biodiesel have two different production processes that create two different types of products: While biodiesel is commonly blended with petroleum diesel at a 5% to 20% ratio, RD is almost chemically identical to petroleum-based diesel.

Fuel the fire

In 1995, PDX began running its buses on compressed natural gas, which still produces emissions but is cleaner-burning than petroleum-based diesel. In July 2021, PDX began procuring renewable natural gas (RNG) for the bus fleet. RNG is biogas captured from organic waste breakdown processes such as landfills, wastewater treatment and agricultural processes.

In February 2022, the Port expanded RD use to its Marine business and is now using it in every piece of container-handling equipment at Terminal 6 that runs on diesel fuel. It’s an average of about 300 gallons of RD a day.

While the cost of RD is slightly higher than petroleum-based diesel, the big savings are in what’s not produced.

“Using RD reduces lifecycle greenhouse gas emissions up to 80 percent,” said Caudill. “It’s also odorless. The scent of diesel is so intense that if even a drop gets on your clothing, you’ll smell like diesel for the rest of the day. But with RD, you won’t smell a thing.”

Because RD burns cleaner than petroleum-based diesel, it reduces equipment maintenance and operating costs. For example, fuel filters, which trap impurities and particulates in fuel, don’t need to be changed or cleaned as often.

Todd Staple, Senior Manager of Marine Maintenance at the Port, agreed. “The transition to R99 is a win-win change for Marine. We will see a significant improvement in carbon reduction at a minimal cost increase to the business line. In addition, we should experience lower maintenance costs overall because of a cleaner-burning fuel and cleaner-burning engine using R99 from previous petroleum-based fuels.”

Leading by example

The Port isn’t the only local organization using RD to fuel up its business. TriMet uses RD for its buses, and the City of Portland and Metro use it as well. Slightly farther afield, Eugene Water and Electric has used RD since 2015.

But one of the crucial ways the Port is leading in this area is not only by example but by its partnerships: By supporting the use of RD, the Port creates demand.

“We have many business partners who also have the need for this type of fuel,” Caudill said. So, we want to help those in the private sector make their way toward using RD.”

Skanska USA and the Port have been in conversation about how Skanska has used RD at the Port’s Terminal Core Redevelopment (TCORE) project, said Joe Schneider, Senior Vice President and Account Manager at Skanska USA. “TCORE started using RD in the summer of 2021, and continues to use RD. The transition has gone well, and Skanska is looking for other large-scale projects to potentially use RD.”

The future is right now

Essentially, RD serves as a bridge strategy. Although many Port vehicles and equipment currently using diesel will convert to electric over time, it won’t happen overnight.

Caudill said, “RD is a strategy we are acting on today to make an impact while also doing the complicated work to plan for future strategies. We are trying very hard to move as quickly as we can: We have a narrow window of time to mitigate the effects of climate change.”